Ultraspin Technology

Treating water with respect

Systems Installed

Installed Capacity (m3/hr)

Megalitres of water treated per year

Milllion Litres of Oil Collected per Year

About

Ultraspin is an engineering company that specialises in the design and supply of high performance oily water separation systems. Our sole focus is oily water which is why we have a high degree of specialist knowledge in all forms of water contaminated with oil, fats and grease across many industries.

Ultraspin invented the use of hydrocyclones in industrial oil water separation systems, with most of our systems using this technology. We export to many parts of the world including Southern Africa, Asia and Europe. We are the largest oily water equipment supplier in Australia.

History

- Ultraspin employees have been designing and supplying high performance oil water treatment systems for over 35 years.

- In 1983 our Engineers designed the worlds first oily water separators using de-oiling hydrocyclones. These systems became standard practice world wide for treating produced water on off-shore oil and gas production platforms.

- In 1993 Ultraspin developed the worlds first industrial oil water treatment system using hydrocyclones. Theses industrial systems incorporated our patented technology that included oil skimmers, separators, strainers and oil collection tanks.

- Based on our philosophy of continual improvement we have racked up an impressive number of ‘firsts’ with our separator technology.

- 1993 worlds first cyclone based oil water treatment system used on Oil Company fuel depots and petrol gas stations.

- 1994 first cyclone based system treating Mining Industry oil water effluent.

- 1995 worlds first cyclone based oil water removal system in the Dairy Industry.

- 1996 first cyclone system treating Meat Industry effluent water allowing tallow and fat recovery.

Meet the Team

Gavan Prendergast - B.Eng (Hons)

General Manager

In 1980, Gavan graduated from Melbourne University with a Bachelor of Mechanical Engineering Honours degree.

Gavan has over 35 years of experience in the oily water industry, spending an extensive amount of time living and working in America and England as well as working in South Africa, Africa and Asia! As a result, Gavan has a plethora of knowledge and experience in a variety of industries such as Mining, Oil and Gas and Food Processing.

In 1983, Gavan designed the world’s first industrial oily water treatment system using hydrocyclones, to treat water and help create a cleaner environment.

It is Gavan’s passion for the environment and desire to help others, that drives him and the Ultraspin team work to achieve better environmental outcomes!

Contact: Gavanp@ultraspin.com.au

Brenton Hornstra - B.Eng, B.Sc

Engineering & Operations Manager

Brenton joined Ultraspin in 2024, bringing with him 15 years of experience in manufacturing and production leadership from the minerals processing and medical device industries. With a double degree in Chemical Engineering (Honours) and Chemistry, he has worked extensively in operations across Australia, the USA, and Africa.

At Ultraspin, Brenton is focused on driving operational excellence, enhancing efficiency, and leading continuous improvement initiatives across engineering, production and servicing.

As our Engineering and Operations Manager, Brenton works closely with our customers to ensure that their needs are met throughout the lifecycle of their Ultraspin system.

Contact: BrentonH@ultraspin.com.au

Lyle Prendergast - B.Eng

Engineering Supervisor

Lyle joined the Ultraspin team in 2017 after graduating from a Bachelor of Mechanical Engineering degree at Monash University.

As Ultraspin’s Engineering Supervisor, Lyle uses computer-aided design software to develop, test and improve Ultraspin’s manufacturing processes and product designs.

Lyle also oversees the Ultraspin lab, conducting performance testing to ensure all of our treatment systems can do what we say they can!

Contact: LyleP@ultraspin.com.au

Jessica Auld - B.Com

Office Manager

Jessica studied a Bachelor of Arts (Public Relations) at Deakin University and graduated in 2014. In 2018, Jess joined the Ultraspin team as our Office Manager!

Jess is the first point of contact at Ultraspin and chances are, if you have called our number, you have spoken to Jess!

Her role also consists of liaising with our suppliers, helping organise the service department and processing and dispatching spare part orders.

Contact: JessicaA@ultraspin.com.au

Janet Liu - B.Eng, B.Sc

Applications Engineer

Janet started at Ultraspin as an Engineering Intern in 2020 and completed a double degree in Mechanical Engineering and Biomedical Science in 2022.

Janet works closely with key Ultraspin customers, building rapport with consultants, end users, and various business partners.

Contact: JanetL@ultraspin.com.au

Sara Molloy - B.Eng

Production and Service Engineer

Sara started at Ultraspin as an Engineering Intern and has been with the company for over three years. After completing her Bachelor of Mechanical Engineering at Monash University in 2022, Sara transitioned to a full-time Production and Service Engineer.

In her current role as a Production and Service Engineer, Sara is crucial to both the manufacturing and customer support aspects of Ultraspin Technology.

On the production side, Sara plays a pivotal role in enhancing the production processes.

On the service front, Sara assists our customers onsite with servicing and commissioning of our systems and provides remote technical support and spare parts assistance from our Melbourne office.

Contact: SaraM@ultraspin.com.au

Kain Kugimiya - B.Eng

Mechanical Engineer

Kain started his full-time role as a Production Engineer at Ultraspin after completing his Bachelor’s degree in Mechanical Engineering at Monash University in 2023. He began his journey with Ultraspin as an Engineering Intern in July 2022.

In his current role, Kain is essential in optimising our manufacturing processes and enhancing product quality. His responsibilities include not only delivering projects and production planning, but also managing our inventory system to ensure efficiency and part availability in production.

Contact: KainK@ultraspin.com.au

Melissa Keatley - B.Eng, B.Sc, M.Teach

Strategy & Operations Consultant

Melissa completed her Bachelor of Science in Chemistry and Bachelor of Engineering with Honours in Chemical Engineering at the University of Melbourne in 2009. Following her passion for continuous improvement and strategic development, she furthered her education with a Master of Teaching, enriching her expertise in adult learning and development strategies.

With 14 years of experience in the oily water industry, Melissa has contributed to sales, service, and operations across global markets including Australia, South Africa, Europe, Asia, and North America. Her expertise is central to driving Ultraspin’s pursuit of excellence in providing effective oily water solutions

Contact: MelissaK@ultraspin.com.au

Nicole Tournas - B.Eng, MBA

Operations Manager

Nicole graduated from Monash University with a Bachelor of Mechanical Engineering degree in 2013.

Nicole completed her MBA at the Melbourne Business School in 2018. As part of her Masters, Nicole went on an exchange program which saw her studying in South Africa!

She has over 10 years of experience in customer service and 8 years of experience in the oily water industry.

Nicole runs the service and spare departments including the servicing and commissioning of our oily water treatment systems.

She also manages our Ultraspin Internship Program which gives student engineers real life, industry experience!

Contact: NicoleT@ultraspin.com.au

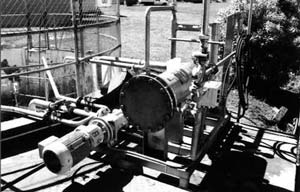

Engineering and Production

Our production facilities and office are located in Wadhurst Drive, Boronia. Our facilities provide areas for warehousing and parts storage, light and heavy assembly as well equipment maintenance and repair. All equipment we manufacture is tested in our wet testing bay prior to delivery.

Ultraspin’s team of employees are experienced and knowledgeable in oil water treatment. Oily water is a highly specialised area of the water treatment industry and Ultraspin is fortunate to have Engineers with an average of over 10 years experience in this industry alone. We have qualified Engineers in all all major disciplines including Mechanical, Chemical and Environmental Engineering. This technical capability is spread across all company activities including Sales, Applications Engineering, Field Support, Production, Process design and ongoing Research and Development.

Design and Drawing Office

All Ultraspin products are designed in house. We have advanced capability using AutoCad, Solidworks and Inventor. This capability enables us to produce a wide variety of drawings including production of schematics, Process Flow Diagrams (PFD), Process and Instrumentation Diagrams (P&ID), Isometrics and piping layouts, Structural designs, Site Layout Drawings, General Arrangements 2D and 3D, and a variety of Electrical Drawing. We are experienced and proficient in the design of equipment skids, structures, piping systems, and pressure vessels to a wide variety of international and client specific standards. We have modern office facilities that caters for 40 office employees.